Repair Services

Polyurethane Crack Injection Sealant

Let SEALED help you to stop or prevent leaks in your basement foundation walls, because a dry basement is a healthy basement. SEALED has assisted hundreds of Kansas City homeowners to make their basements dry and healthy.

How it works

Determining a repair type

At SEALED we know basement cracks and leaks, and much of our work involves crack injection. We begin with an assessment of the type, size, and dimensions of each foundation crack in your home.

Narrow cracks running vertically and diagonally from hairline to 1/4″ in width are common in many poured foundation walls. They might appear due to settling, wide temperature variations, or pressure from the surrounding clay soil. And most are good candidates for polyurethane crack injection.

However, If the crack is larger than 1/4″ or we believe you have significant structural problems, SEALED may suggest a carbon fiber repair. Or if more significant structural damage is apparent, SEALED will suggest other solutions. Importantly, if a crack is actively leaking water, we need to ensure that the surface of the concrete is dry before we begin our crack injection work. The epoxy we use to cover cracks and anchor ports will quickly liquefy when wet.

The process

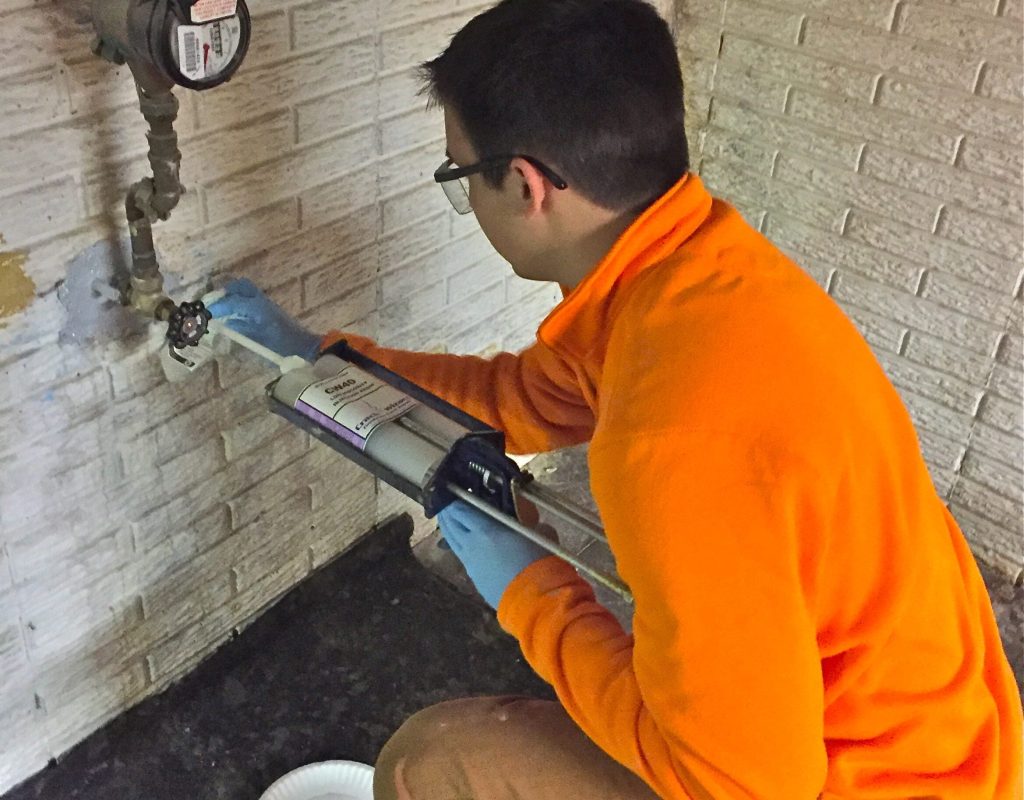

Crack injection with expanding polyurethane

To begin our work, a SEALED technician will grind and brush all paint, varnish, dirt, etc. away from the area around the foundation crack. In some cases, extensive efforts are required to remove an attempted but unsuccessful DIY repair. It is important that the area surrounding the crack is just bare concrete, to ensure the best adhesion. Though a small amount of dampness is no hindrance, we may also need to dry up any leaks or moisture after a recent rain.

Next, we will coat the entire area with fast setting epoxy. After applying a thin coat the SEALED tech may affix a strip of fiberglass tape over the crack and then apply a second thin coat of epoxy. This strengthens the seal and requires less total epoxy, resulting in quicker curing. This method seals the crack from the inside of your home and ensures that our injected material will remain behind this seal or cap. In some cases, we will apply backer rod to any large voids. As the SEALED tech applies the epoxy, they will place small plastic ports over the open crack at intervals. The ports indicate where we will inject the liquid polyurethane. And even where the width of the crack is small, the low viscosity liquid polyurethane will be able to be injected into the crack without drilling. The epoxy must then be allowed to completely dry, a process that can take up to 90 minutes.

Finally, SEALED will inject a water-activated liquid polyurethane into the ports and throughout the crack. This material expands to several times its original volume in the presence of water. This expansion will force the polyurethane into all the crevices and chambers in the foundation wall, even where we can’t see them from the surface. The polyurethane will form a moisture seal all the way through the wall, (approximately 8″) but will retain some flexibility. This property accommodates any minor settling which might occur after the SEALED repair is completed.

The polyurethane cures very quickly and your cracks are now repaired. After 24 hours have passed, you may remove the ports with a hammer and a chisel. The concrete surface can then be lightly sanded and painted. If you do elect to sand the epoxy seal, be sure to wear safety glasses and a full-face respirator.

And remember, cracks which SEALED has repaired carry a fully transferable 10-year warranty against leaks!

Ready to start a project?

SEALED offers free inspections and estimates on all poured foundation crack repair Jobs. Drop us a line anytime, and one of SEALED’s Kansas City crack repair experts will respond to you as soon as possible.